Purpose and applications

Modules with generator circuit breaker series SV-1 are designed for reliable and cost efficient protection of max.125 MW power generation units, for transfer of 50 and 60 Hz generator voltage from generator to unit transformer and for breaking short circuit currents in emergency operation modes.

They perform all switching operations at the time of generator starting and stopping.

Applications include various power plant types (thermal, nuclear, hydraulic) including PSH г, gas and steam power plants as well as power plants fueled by coal, solar energy and geothermal energy sources.

Operating conditions

Modules are manufactured for outdoor operation with nominal values of climatic factors according to GOST 15150, GOST 15543.1 climatic version T, location category 3.

- maximum installaton altitude above sea level – up to 1,000 m;

- upper operating value of ambient temperature for climatic version T, location category 3 - plus 40°C (maximum value - plus 45°C);

- lower value of operating ambient temperature for climatic version T, location category 3 - minus 45°С (maximum value - minus 50°C);

- relative air humidity - 75% at 15°С (mean annual value); upper operating value of relative air humidity 98% at 25°С, for climatic version T, location category 3.

Normal mode of operation of generator modules under the operating conditions must be ensured for atmosphere types II, III, IV according to GOST 15150. The environment must be free of water vapors and current conducting dust in concentrations that may interfere with the operation of the generator module, and it must be explosion safe.

Nominal operating values of mechanical external factors are according to GOST 17516.1 for structural design category М5. Seismic resistance is 8 points at the altitude of 25 m, 9 points MSK at the altitude of 10 m.

Protection degree of generator modules is IP65 according to GOST 14254.

Modules are manufactured in accordance with TU 3414-001-90066304-2012.

Main technical data

|

Type of the generator module |

Nominal voltage, kV |

Nominal curent, А |

Nominal short circuit breaking current, kA |

Industrial frequency test voltage, kV |

Lightning pulse test voltage, kV |

|

1 |

2 |

3 | 4 | 5 | 6 |

| SV-10,5-4000-63 U3 | 10,5 | 4000 | 63 | 42 | 75 |

| SV-15,75-4000-63 U3 | 15,75 | 4000 | 95 | ||

| SV-10,5-5000-63 U3 | 10,5 | 5000 | 75 | ||

| SV-15,75-5000-63 U3 | 15,75 | 5000 | 95 | ||

| SV-10,5-6300-63 U3 | 10,5 | 6300 | 75 | ||

| SV -15,75-6300-63 U3 | 15,75 | 6300 | 95 |

Design

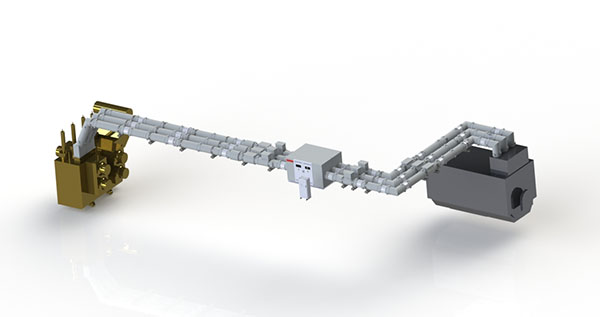

Generator module series SV-1 is a finished, compact and fully equipped product.

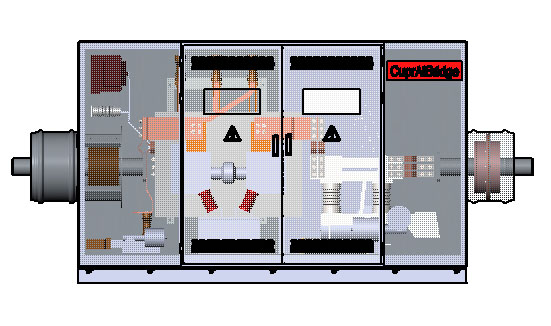

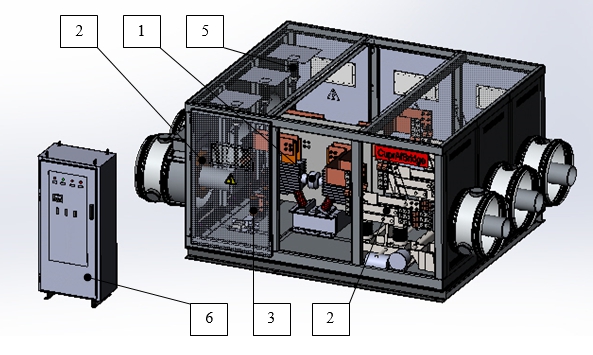

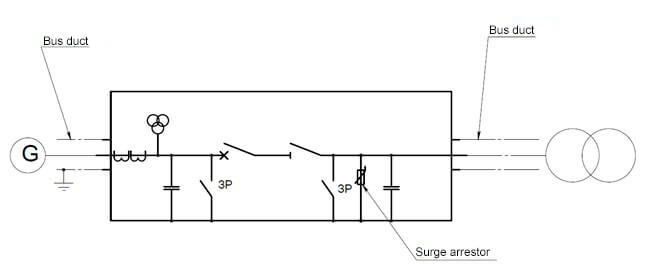

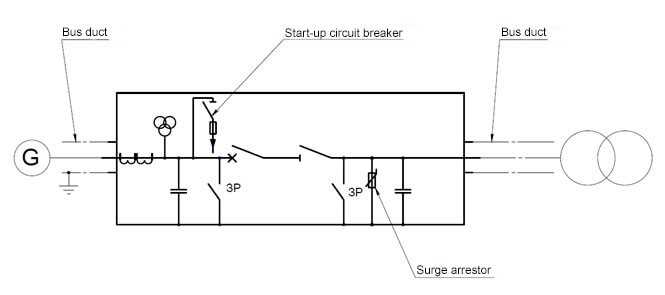

It consists of an air-insulated metal housing, inside which the equipment (vacuum circuit breaker, earthing connector, circuit breaker, etc.) is installed. The primary type of generator vacuum circuit breaker in use is 3AH37 by Siemens. The composition of the generator module is shown in Fig.1.

The housing of the generator module is made of aluminum with bolted and welded joints. Internal structural parts of the housing can be made of stainless steel or ferrous metal with powder coating. The housing of the generator module is painted with powder epoxy coating. The main painting color is RAL 7035. Upon customer’s request, a different color may be used. Monitoring windows and manholes are provided for controlling all switching devices by means of emergency systems.

Control cabinet and actuators of switching devices are installed on the outer surface of the generator module housing. Fixed mounting is used for all the switching devices. The housing of the generator module in all attachment points is isolated from building structures by means of insulating gaskets and insulation bushings. Holes in support assemblies are oval to allow for movements in case of thermal expansions.

There are welded joints between output buses of the generator module and bus duct on the side of the turbine generator and the power transformer. Inspection windows are provided on the generator module cover to watch over plug contacts, circuit breakers and earthing connectors.

Figure 1

1-Vacuum circuit breaker; 2-circuit breaker; 3-earthing connector; 4-current transformer; 5-surge arrestor; 6-control board

Control cabinet is designed as a self-contained module that ensures safe working of operators inside it; it is isolated from the GSG housing. The control cabinet is sealed to prevent any ingress of dust and moisture. Standard configuration of the control cabinet includes the equipment based on assignments of design organizations agreed with the manufacturing plant.

Single-line diagrams of the generator module

Diagram 01

Diagram 03

Scope of supply

Following is included into the scope of supply:

- generator switchgear;

- control cabinet;

- assembly drawing of the device (dimensional and installation drawing);

- bill of materials;

- spare parts list (upon customer’s request);

- technical description and operation manual;

- data sheet.